The Hybrid Cylinder technology has been sophisticatedly researched & designed to enable the re-use of either existing gravure printing cylinders or newly commissioned light weight alternatives which are crucially diameter/circumference size variable, as required by the end user.

The Hybrid gravure cylinder is compatible with all metal plating technologies and requires no added equipment or infrastructure, sleeves or adapters for the engraver or printer and the Hybrid Gravure Cylinder will work seamlessly with the existing gravure industry infrastructure.

Additionally the Hybrid Cylinder system is a fully automated manufacturing operation that can be incorporated into existing gravure cylinder processing & handling automation systems.

Key Benefits:

- The new Hybrid Cylinder can be shipped from the manufacturing plant in as little as 48 hours after the initial order.

- The Hybrid Cylinder production rate is approximately 6 cylinders per hour per machine.

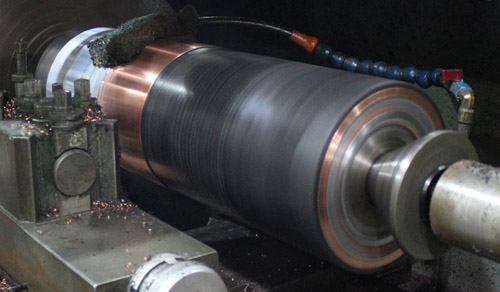

- The off the shelf nature of the Hybrid Cylinder allows for printers and/or their engravers to resize a cylinder onsite, plate it, engrave it and have it on the press in a couple of hours, with set up times to rival flexo, all with existing gravure equipment.

- Per cylinder, the use of Hybrid Cylinders offers the gravure printer up to an average 50% cost reduction over traditional cylinder technology.

- The Hybrid Cylinder product can also be used in combination with advanced Monolayer Nickel plating systems.

- Using the Hybrid cylinder system it is feasible to reduce stored cylinder stocks to a fraction of current levels.

- Hybrid Cylinders offers identical performance to the current non Hybrid ‘gravure printing ‘ cylinder and works seamlessly with existing gravure processes without adaptors, sleeves, increased labour costs or additional equipment.

Re-size Onsite with 94mm size variation

The off the shelf nature of the Hybrid Cylinder allows for printers and/or their engravers to resize a cylinder onsite, plate it, engrave it and have it on the press in a couple of hours in order to rival flexo giving 94mm size variation on circumference on launch, then rising to 157mm on size variation circumference later in 2015.

Lightweight Cylinders (<25kg)

For smaller gravure cylinders such as in the label market, the Hybrid Cylinder can be engineered lightweight (<25kg) to be suitable for easy handling, thus dispensing the need for cranes and further reducing turnaround times, which facilitates more print efficiencies.

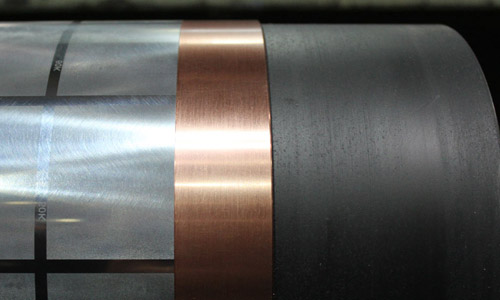

Breathing Life into Old Cylinders

For printers considering investment in new gravure print presses, the cost of acquiring the cylinders for the new press can be considerable and often more expensive than the new press itself. With Hybrid Cylinder technology, the overall investment is significantly reduced, making gravure a more attractive print operation.

The Hybrid Cylinders team comprises third generation gravure industry expertise and leading polymer specialists and engineers with the common goal of delivering a hybrid cylinder technology for the gravure printing market.

For those wishing to register an interest in the Hybrid Cylinder, please use this ‘Register’ function.